If you're hanging pictures or putting together a bookcase, a hammer is a perfect tool: simple, cheap and entirely effective. But if you're building a two-story house, installing hardwood floors or running your own furniture repair shop, you may want to spring for a nail gun. These powerful machines launch nails at high speed, fully embedding them in a piece of wood in only a fraction of a second. Obviously, such a machine can save you hours of toil and sweat. They take almost all of the work out of nailing.

Advertisement

In this article, we'll find out how these popular machines launch nails at such astounding speeds. As it turns out, there are a wide variety of nail guns on the market, employing a range of physical principles.

Spring-loaded Design

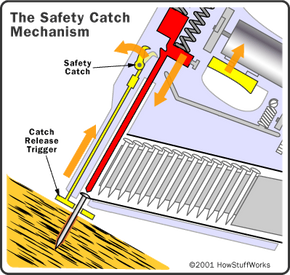

At its most basic level, a nail gun has only two jobs:

- It needs to concentrate a great deal of hammering force into a single mechanized blow, which can be repeated rapidly.

- It needs to load a new nail after the previous nail is ejected.

There are any number of machines that could handle these tasks. Since we can't look at every single model, we'll investigate a few representative designs.

The simplest nail guns use ordinary springs to generate the hammering force.

Here's what happens when you pull the trigger:

- The triangular cam turns, pushing down one end of a lever (c).

- The lever pivots, pushing up on the hammer (d). As the hammer pushes up, it compresses two springs (e).

- The hammer has a small knob (f) attached to one end. As the lever pushes the hammer up, the turning scooper plate catches hold of this knob. At the same time, the rotating cam (b) releases the lever, which releases the hammer. The hammer is now held in place by the scooper plate.

- As the scooper plate turns, it lifts the hammer higher and finally releases it.

- The two compressed springs drive the hammer downward at high speed. If a nail is in position, the hammer launches it from the gun.

On the next page, we'll take a look at the nail-loading mechanism.