According to Doug Milliken, author of the racing bible, "Race Car Vehicle Dynamics," legendary race car driver Barney Oldfield coined the term plowing. Oldfield was racing a front-heavy car on a dirt track when he took a corner at a high speed. Rather than fully direct the car into the turn, the front wheels continued their forward momentum, creating trenches in the track the way a plow would. Oldfield's estimation of the problem was summed up in the term he's thought to have invented [source: CMA Consulting].

Today, plowing is still in use. It describes the effect of understeering, essentially when the forward momentum carries front wheels straight ahead, rather than in the direction of the corner they're turned into. Since the steering wheel has turned the front wheels, they are no longer aligned straight ahead. Instead, they create flat edges that dig into the ground rather than roll smoothly along on top of it, as they're designed to.

Advertisement

On a dirt track, plowing can create divots. On a hot asphalt track it can shred tires. And when a rider mower plows, it can cause some serious turf damage.

When a tire loses contact with the ground -- whether a track or a lawn -- the other tires can lose control and lead to sliding or even rolling. Depending on the grade of the incline that the machine is on, this can be bad news for anyone aboard.

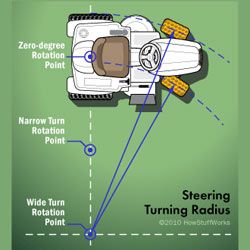

This is precisely why the Synchro-Steer system was created. Designed by Cub Cadet engineers in 2009, Synchro-Steer is intended to lend the most control possible to rider mowers. The system allows for a zero-turn radius, meaning the entire mower pivots on a single point along the axle of the rear wheels. The Synchro-Steer system isn't the only zero-turn system, but it has the added benefit of four-wheel control. This cuts down on plowing, leading to less turf damage, and provides greater stability and traction regardless of weather conditions or the grade of an incline that requires mowing.

To truly appreciate what Synchro-Steer is all about, let's take a quick look at the physics of steering and what the system is intended to overcome.

Advertisement