Key Takeaways

- Start with basic hand tools for wooden furniture restoration and gradually add power tools like a variable-speed drill, which facilitates tasks such as drilling and can be equipped with various attachments.

- Invest in quality tools even if the cost is slightly higher, as they last longer, perform better and ensure safety better than cheaper alternatives.

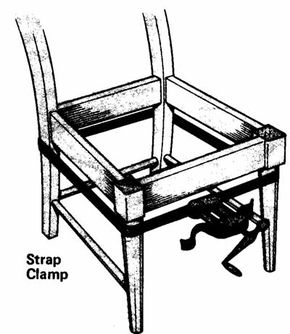

- Essential tools for a woodworking workshop include clamps, saws, chisels, screwdrivers and a combination of hand and power tools to handle a wide range of furniture restoration tasks.

Furniture repair and refinishing are jobs for hand tools. Certain power tools will make the work go faster and easier, but learn how to use the hand tools first. In this article, we'll discuss the best tools to include in your at-home workshop, including secondary tools that aren't necessary for repairs but can shorten your work time.

The only exception to consider is a portable electric variable-speed drill. With this power tool, you can make fast work of drilling holes in almost any material. Many drills are available with a large variety of accessories: saws, grinders, lathes, and the like. Buy the accessories as you need them. Start out with the basic drill and an assortment of drill bits. A cordless drill requires no electrical outlet and can be used outside.

Advertisement

One final word on buying tools: buy quality tools. Buy them all at once or one tool at a time, as your budget permits. Cheap tools are a waste of money and can cost you plenty in miscut and poorly cut materials. Cheap tools can also be dangerous because they don't hold a sharp cutting edge, and dull tools can slip.

Quality tools are well balanced, carefully machined, expertly matched, and properly heat-tempered. With some care, quality tools will last you a lifetime. The cost difference between a quality tool and a cheap tool is just a matter of a few dollars.

Buying quality tools involves a little comparison-shopping. Most home center and hardware stores have a "good, better, and best" tool display. You can easily spot the difference between a quality tool and a cheap tool by comparing one with the other. A quality tool will be well machined and look it. Cheap tools look like they came out of a poorly formed mold. The metal will be rough and sharp, or, at best, sometimes filed smooth along the sharp parts.

Once you know what you want, check prices on ebay and other online stores to make sure you get the best deal.

Primary Tools

Listed below are the basic tools for furniture projects. If your budget permits, buy them all at the outset. If not, your primary selection should include scrapers, a hammer, a hacksaw, screwdrivers, a utility knife, a craft knife, and three sizes of clamps.

Scrapers: Putty knife, pull scraper, pull scraper blade, smooth-cut file, rubber spatula.

A stiff-bladed putty knife can be used as a scraper in cramped quarters, and it is useful when applying wood filler. A pull scraper removes old finish fast--right down to the bare wood. A furniture scraper is made for furniture; it's sold primarily at furniture specialty stores. If you can't find one, buy a regular flat scraper blade; it will work fine. Be sure you keep the scrapers sharp at all times with a smooth-cut file. Scraper edges become dull fairly quickly; you'll probably have to resharpen them two or three times during a refinishing project.

Hammers: 13-ounce claw hammer, ball-peen hammer, rubber or wooden mallet (or both).

A 13-ounce claw hammer is easier to swing than a standard 16-ounce hammer. Generally, you don't need the extra whacking power the heavier hammer provides, and the smaller hammer can also go into tighter quarters. A ball-peen hammer is designed for metalwork; one end of the hammerhead is rounded for flattening rivets. The soft faces of a rubber or wooden mallet are designed for driving chisels, and you will also need them to tap wooden furniture components into position.

If you can find one, buy a cross-peen hammer instead of a 13-ounce hammer. This tool has a flat face for heavy pounding and a smaller peen face to use in corners and tight quarters. Most tool outlets (hardware and home center stores) don't carry this hammer, but you can usually order it.

Measuring Tools: Combination square, steel ruler (24 inches long), 25-foot tape measure, friction-point calipers, bradawl or ice pick, utility knife with blade assortment.

Most furniture components are fairly small, so you don't need a large carpenters' square for marking and checking square cuts. A combination square with a removable blade is the best tool -- use it for a depth gauge, for angles, as a ruler, and as a straightedge with the blade removed from the handle. A steel ruler is needed for a straightedge more than for measuring. The markings, however, will be helpful.

Friction-point calipers are used to determine sizes of rounds (dowels and turnings), and they will save you plenty of time trying to match components.

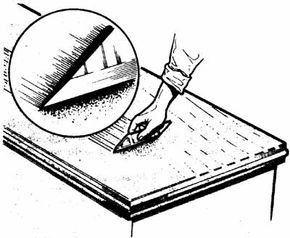

The bradawl (or ice pick) and utility knife are used to mark cuts on furniture. Do not use a pencil; the pencil point quickly wears flat, resulting in inaccuracy. You can easily see a light knife cut or scratch line from the point of a bradawl, and you get accuracy in the bargain.

A 25-foot flexible steel tape measure with a wide blade is tops for general measurements (rough materials, for example). The wide blade is stiff so you can pull out a fairly long length of tape without it bending and/or drooping.

Not sure what other tools to include in your at-home workshop? Check out the list continued in the next section.

Advertisement