The human-end of making a copy begins with a few basic steps:

- Open the copier lid

- Place the document to be photocopied face-down on the glass

- Select the options you want (number of pages, enlargements, lighter/darker)

- Press the Start button

What happens inside the copier at this point is amazing! At its heart, a copier works because of one basic physical principle: opposite charges attract.

As a kid, you probably played with static electricity and balloons. On a dry winter day, you can rub a balloon on your sweater and create enough static electricity in the balloon to create a noticeable force. For example, a balloon charged with static electricity will attract small bits of paper or particles of sugar very easily.

A copier uses a similar process.

- Inside a copier there is a special drum. The drum acts a lot like a balloon -- you can charge it with a form of static electricity.

- Inside the copier there is also a very fine black powder known as toner. The drum, charged with static electricity, can attract the toner particles.

There are three things about the drum and the toner that let a copier perform its magic:

- The drum can be selectively charged, so that only parts of it attract toner. In a copier, you make an "image" -- in static electricity -- on the surface of the drum. Where the original sheet of paper is black, you create static electricity on the drum. Where it is white you do not. What you want is for the white areas of the original sheet of paper to NOT attract toner. The way this selectivity is accomplished in a copier is with light -- this is why it's called a photocopier!

- Somehow the toner has to get onto the drum and then onto a sheet of paper. The drum selectively attracts toner. Then the sheet of paper gets charged with static electricity and it pulls the toner off the drum.

- The toner is heat sensitive, so the loose toner particles are attached (fused) to the paper with heat as soon as they come off the drum.

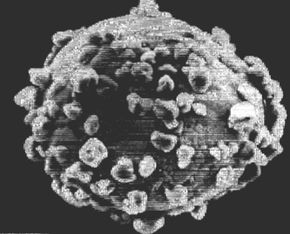

The drum, or belt, is made out of photoconductive material. Here are the actual steps involved in making a photocopy:

- The surface of the drum is charged.

- An intense beam of light moves across the paper that you have placed on the copier's glass surface. Light is reflected from white areas of the paper and strikes the drum below.

- Wherever a photon of light hits, electrons are emitted from the photoconductive atoms in the drum and neutralize the positive charges above. Dark areas on the original (such as pictures or text) do not reflect light onto the drum, leaving regions of positive charges on the drum's surface.

- Negatively charged, dry, black pigment called toner is then spread over the surface of the drum, and the pigment particles adhere to the positive charges that remain.

- A positively charged sheet of paper then passes over the surface of the drum, attracting the beads of toner away from it.

- The paper is then heated and pressed to fuse the image formed by the toner to the paper's surface.

When the copier illuminates the sheet of paper on the glass surface of a copier, a pattern of the image is projected onto the positively charged photoreceptive drum below. Light reflected from blank areas on the page hits the drum and causes the charged particles coating the drum's surface to be neutralized. This leaves positive charges only where there are dark areas on the paper that did not reflect light. These positive charges attract negatively charged toner. The toner is then transferred and fused to a positively charged sheet of paper.

Inside a Photocopier

If you take a photocopier apart, you might be overwhelmed by how many different parts there are. However, the actual photocopying process relies on only a few, key pieces:

- Photoreceptor drum (or belt)

- Corona wires

- Lamp and lenses

- Toner

- Fuser

In the following sections, you'll learn about each of these parts.