Key Takeaways

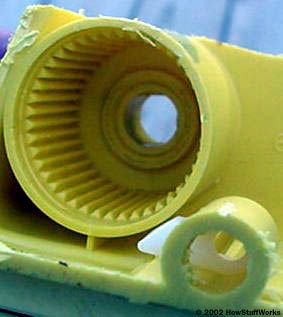

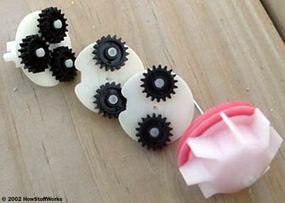

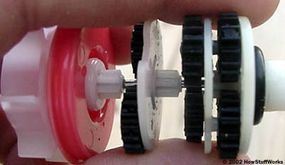

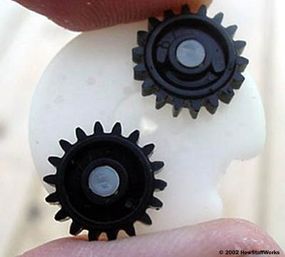

- Oscillating sprinklers work by using a simple mechanism where water flows into a spray arm, which has a series of holes or nozzles. A heart-shaped cam pushes it back and forth to ensure even water distribution across the spray pattern.

- The heart-shaped cam ensures that both ends of the spray pattern receive the same amount of water as the center, preventing the uneven distribution that a circular cam would cause.

- This type of sprinkler is a popular choice for garden and lawn care due to its simplicity, effectiveness and ability to cover a wide area evenly.

If you have a lawn, then at some point during the summer, when it gets really hot and dry, you end up pulling out the sprinkler...

An oscillating sprinkler like the one shown above is one of the most common sprinklers around. It sprays out a fan-shaped curtain of water, and the metal arm oscillates back and forth to cover a rectangular area perhaps 20 feet by 30 feet (6 meters by 9 meters) in size.

Advertisement

If you've thought about it for more than five seconds, you've probably wondered about the "oscillating" part of an oscillating sprinkler: What makes the arm go back and forth? In this edition of HowStuffWorks, you'll learn exactly how it happens!

Advertisement