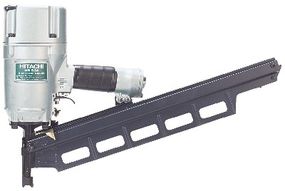

Pneumatic Nail Guns

The most popular sort of nail gun is the pneumatic nailer. In these machines, the hammering force comes from compressed air, typically generated by a separate gas-powered air compressor. A standard air compressor works on the same principle as a water pump. It has one or more piston cylinders, which draw air in from the atmosphere on the upstroke and push it out to the gun on the downstroke. This generates a constant supply of compressed air, which flows through a hose into the gun's air reservoir.

A pneumatic nailer uses the same sort of hammer as a solenoid nailer: It has a sliding piston that drives a long blade. When the air pressure above the piston head is greater than below it, the piston is forced downward. When the air pressure below the piston is greater than above it, the piston stays up. The trigger mechanism serves to channel the flow of compressed air to shift this balance.

Advertisement

For example let's say a movable valve plunger (a) sits above the piston head (b). When the trigger is in the released position, compressed air can flow to both sides of the valve plunger. It flows directly through the air reservoir to a lip around the bottom of the plunger, through the trigger valve (c) and a small plastic tube (d) until it reaches the area above the plunger. Since compressed air flows to both sides of the plunger, air pressure balances out. But the plunger is also attached to a spring (e), which pushes it downward. This shifts the pressure balance: When the trigger is released, there is always greater pressure above the plunger than below it.

This imbalance keeps the plunger pressed against the seal surrounding the piston head. With the plunger in this position, the compressed air flowing into the gun can't reach the top of the piston to push it down.

Here's what happens when you pull the trigger on a pneumatic nail gun:

- The trigger valve closes and opens a passageway to the atmosphere. With the trigger valve in this position, the compressed air can't flow to the area above the valve plunger.

- There is greater pressure below the plunger than above it. The plunger rises up, and the compressed air makes its way to the piston head.

- The compressed air drives the piston and the blade downward, propelling the nail out of the chamber.

- As the piston slides downward, it drives the air inside the cylinder through a series of holes, into a return air chamber (f).

As more air is pushed into the chamber, the pressure level rises. When you release the trigger, compressed air pushes the plunger back into place, blocking the air flow to the piston head. With no downward pressure, the compressed air in the return air chamber can push the piston head back up. The air above the piston head is forced out of the gun, into the atmosphere.

Pneumatic nail guns work very well, even at driving thick nails through hard material. But they are somewhat cumbersome tools: You need to drag around a bulky air compressor to power one. In the next section, we'll look at a high-powered nail gun design that doesn't need an external power source.

Check out the next page to learn about combustion nail guns.