Modern industry depends on the manipulation of heavy metal and alloys, as we need metals to build the tools and transportation necessary for day-to-day business. For example, we build cranes, cars, skyscrapers, robots, and suspension bridges out of precisely formed metal components. However, humankind would have an incredibly tough time building any of these things without the advancements of plasma cutting.

Metals are extremely strong and durable, so they're the logical choice for most things that need to be especially big, especially sturdy, or both. Yet, the funny thing is that metal's strength is also a weakness. Because metal is so good at resisting damage, it's very difficult to manipulate and form into specialized pieces. So how do people precisely cut and manipulate the metals needed to build something as large and as strong as an airplane wing?

Advertisement

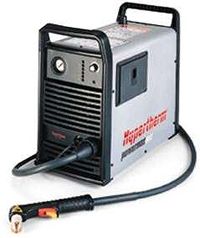

In most cases, the answer is the plasma cutter. It may sound like something out of a sci-fi novel, but the plasma cutter is actually a common tool that has been around since World War II. Conceptually, a plasma cutter is extremely simple. It gets the job done by harnessing one of the most prevalent states of matter in the visible universe. In this article, we'll cut through the mystery surrounding plasma cutting and see how one of the most fascinating tools has shaped the world around us.