Repairing Motors

Major appliance motors are usually dependable and long-wearing. You can prolong their life and increase their efficiency by keeping them clean and well lubricated. Use motor-driven appliances sensibly. Don't overload them, don't abuse them, and don't ignore problems until they become serious.

There are several basic rules for operating motor-driven appliances:

Advertisement

- Always connect an appliance to an adequate power source; a 220-240-volt appliance must be connected to a 220-240-volt outlet. If the outlet for a major appliance is not grounded, use a grounded adapter plug to ground the appliance.

- Never use a small appliance that's wet, and never operate any appliance while your hands are wet. If a large appliance, such as a washer or dryer, gets wet, do not operate it or try to unplug it. Have the motor examined by a professional before you use the appliance again.

- Never overload an appliance. Overloading causes inefficient operation and motor overheating, and can cause excessive wear. If a motor turns off because it's overloaded, reduce the load before restarting the appliance.

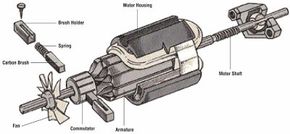

Universal MotorsUniversal motors consist of a rotor called an armature, with coils of wire wound around it, and a rotating cylinder called a commutator, with alternating strips of conducting and nonconducting material. The armature and the commutator are both mounted on the motor shaft. On each side of the commutator, a carbon brush carries current from the circuit. When the carbon brushes press against the commutator, the armature is magnetized and rotates. Most universal motors also have a cooling fan at the end of the shaft. Universal motors are used in many small and medium-size appliances. They provide strong power at both low and high speeds. Universal motors can operate on either AC or DC current. Their speed is controlled by a rheostat, a tapped-field control, a rectifier, or a governor, or by physical movement of the carbon brushes away from the armature.

Most universal motors are permanently lubricated and sealed by the manufacturer and require no further attention. Some universal motors, however, have covered lubrication ports, usually marked "oil," at the ends of the motor shaft. This type of motor should be oiled every six months, or according to the manufacturer's instructions. Lift each port's lid and apply a drop or two of No. 30 nondetergent motor oil (not all-purpose oil). Do not over-lubricate.

Many universal motor malfunctions are caused by wearing down of the carbon brushes, the soft blocks of carbon that complete the electrical contact to the motor's commutator. When these brushes become worn, the motor will spark, and electrical contact may be incomplete. You can solve both problems by replacing the brushes.

Brushes can be checked visually or tested with a continuity tester. Here's how:

Step 1: To sight-check the carbon brushes, remove the screws that hold the brushes and brush springs into the brush holders at the sides of the commutator. The screws will pop out of the screw holes; turn the motor over to tap out the brushes. The ends of the brushes should be curved to fit the commutator; if they're worn down, new brushes are needed.

Step 2: To check carbon brushes with a continuity tester, remove the motor lead wires from the circuit. Tag the wires as you disconnect them so that you'll be able to reconnect them properly. Hook the tester clip to one motor lead and touch the probe to the other lead; the tester should light or buzz. Slowly rotate the motor shaft, keeping the tester in position. If the tester doesn't light or buzz, or if it flickers or stutters when you turn the motor shaft, the brushes should be replaced. If the springs behind the brushes are damaged, they should be replaced as well.

Step 3: Replace worn carbon brushes and damaged springs with new ones made specifically for the motor. The model information (number and make) is stamped on a metal plate fastened to the motor, or embossed on the metal housing of the motor. If you can't find the model information, take the worn brushes and springs with you to an appliance-parts store to make sure you get the right kind. Insert the new springs and brushes in the brush holders, replace the brush assemblies, and secure the new brushes with the mounting screws that held the old brushes.

Don't attempt other repairs to a universal motor. If a serious malfunction occurs, buy a new motor or take the faulty motor to a professional for repairs. Most large universal motors are fastened to plate-type mountings. To remove the motor, disconnect the wires and remove the holding bolts and any belts that are present. If the faulty motor is in a small appliance, take the entire appliance to the repair shop. It may sometimes be less expensive to buy a new appliance than to have the old one repaired.

Split-Phase Motors

Split-phase motors consist of a rotor turning inside a stator (the non-moving portion of a motor) that has two wire coils: a starting winding and a running winding. Current flows through both windings when the motor is starting up, but when the rotor has reached about 75 to 80 percent of its top speed, the starting winding is turned off and only the running winding receives current. Split-phase motors operate on AC current. They are fairly powerful, and are used in appliances such as washing machines, dryers, and dishwashers.

These motors require no maintenance except cleaning and lubrication. Split-phase motors have a special auxiliary winding -- the starting winding. Don't try to make any repairs yourself. When a motor malfunctions, buy a new motor or take the faulty motor to a professional service person, whichever is less expensive. You can save the expense of a service call by removing the old motor from its mounting and installing the repaired or new motor yourself.

Capacitor-Start Motors

A capacitor-start motor is a shaded-pole motor with a capacitor (an energy-storing device) wired into the starting winding. The capacitor stores current and releases it in bursts to provide extra starting power. When the motor reaches about 75 percent of its top speed, the starting winding is turned off. Capacitor-start motors operate on AC current. They are very powerful and are used in appliances that require a high starting torque or turning power, such as air conditioners and furnaces.

Capacitor-start motors require regular cleaning to keep them free of lint and oil. Ventilation to the motor must be adequate. If the motor has oil ports, lift each port's lid and apply a drop or two of No. 30 nondetergent motor oil (not all-purpose oil). Do not over-lubricate.

Capacitor-start motors are usually hard to get at and have a capacitor and special auxiliary windings. Don't try to make any repairs yourself. When a motor malfunctions, call a professional service person.

Caution: Capacitors store electricity, even after the power to the appliance is turned off. When working with a capacitor-start motor, you must discharge the capacitor with a 20,000-ohm, 2-watt wire-wound resistor, as detailed for each appliance.

As with most do-it-yourself projects, repairing your own household appliances can save you both time and money. If you can remember to take it slow and label your steps, you can disassemble and reassemble most of the simple machinery in your home.

©Publications International, Ltd.