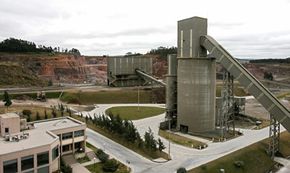

You walk past miles of the stuff everyday. It's in your home, your office and every store you visit. It has many names: Sheetrock, wallboard, plasterboard, gypsum wallboard, or most commonly, drywall. Despite the prevalence of drywall in our everyday lives, very few people know how it's made, where it comes from or how useful this material really is.

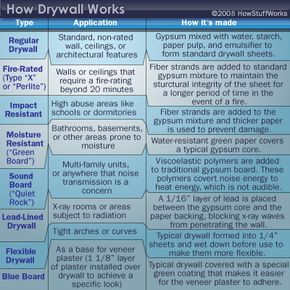

Drywall is a construction material used to create walls and ceilings. It's also used to create many design features, including eaves, arches and other architectural specialties. It's quick and easy to install, incredibly durable, and requires only simple repairs when damaged. In the commercial building world, drywall is used to wrap columns to conceal steel beams and is an easy and inexpensive way to top off masonry walls above ceilings. Drywall is also used to add fire resistance at walls and ceilings, containing the spread of fire so people can evacuate safely during an emergency.

Advertisement

Before drywall became widely used, building interiors were made of plaster. For hundreds of years, walls and ceilings have been constructed by placing layers of wet plaster over thousands of wooden strips called laths. The wet plaster would eventually harden to form walls, but the installation and repair processes were both time-consuming and difficult to do well. Creating plaster walls required several coats to be applied, with a long drying time in between each coat. In addition to its extended installation period, plaster application was quite labor-intensive, requiring skilled craftsmen who labored over a small area of a wall for weeks on end.

Walls that would take weeks to create with plaster could be finished in a couple of days with drywall and would last longer and cost less to build. Damaged drywall can be patched up in a quicker and easier fashion than plaster, and drywall also has a greater degree of fire-resistance.

Despite all these benefits, the use of drywall was slow to catch on with builders. It was only in the past 50 or 60 years that this material truly gained any respect. Let's take a look at the history of drywall and see how its reputation evolved over the years to become a universally favored building material.

Advertisement