Controls

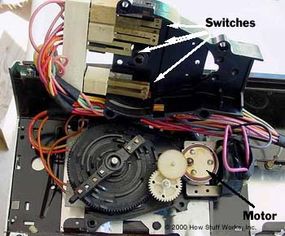

The controls for this machine were designed before microcontrollers were being used in appliances. In fact, there is not a single resistor or capacitor in the whole machine. First, let's take a look at the cycle switch -- you'll be amazed at what is inside.

The cycle switch has the job of determining how long the different parts of the cycle last.

Advertisement

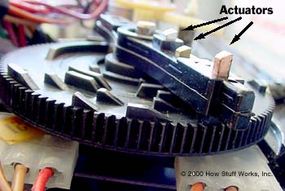

Inside the switch is a little motor equipped with a very large gear reduction that makes the control dial turn very slowly. In the top half of the switch, there is a set of six contacts. These are actuated by the small pieces of metal in the plastic arm on the dial. As the dial spins, bumps on the dial raise and lower the six metal pieces, which close and open the contacts in the top half of the switch.

If you look at the shape of the bumps, you can see why the dial on the washer spins only one way: The front side of the bumps has a slope that raises up the metal pieces gradually; but the back side doesn't, so if you try to turn the knob backward, the metal pieces wedge against the bumps.

This bumpy plastic disk is really the software program that runs your washing machine. The length of the bumps determines how long each part of the cycle lasts, and the length of the space between bumps determines how long the machine pauses before moving on to its next task.

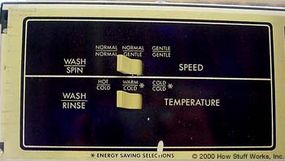

The speed and temperature control switches are much simpler than the cycle control switch.

These switches control the speed of the motor and determine which of the hot/cold water supply solenoids will open during the wash and the rinse cycles. If hot is selected, only the hot water solenoid valve will open when the machine fills; if warm is selected, both will open; and if cold is selected, only the cold water solenoid valve will open.

The speed/temperature control is pretty simple. Each plastic rocker engages two sets of contacts, either opening or closing the circuit connected to those contacts. For each switch, there is always one closed and one open set of contacts.

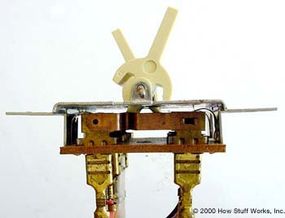

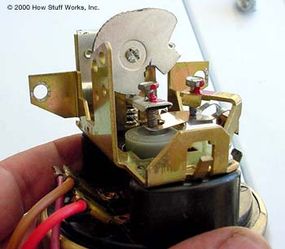

The level sensor uses a pressure switch to detect the water level in the tub.

This switch controls how high the tub fills with water.

The big end of the hose connects to the bottom of the tub, while the small end connects to the switch. As the water level in the tub rises, water rises in the hose also; but the air in the hose is trapped, so as the water rises, the air is compressed.

Inside the housing of this switch is a little piston. The pressure in the hose pushes the piston up. When it is raised far enough, it pops up and closes an electrical contact. This set point, where the contact is lost, is adjustable, and in the picture you can see the cam mechanism that is connected to the adjuster knob on the control panel of the washer. As the cam turns, it presses a spring against the cylinder, making it harder for the cylinder to pop up. This means that the water level will have to rise some more before the pressure in the hose will be high enough to trigger the switch.

For more information, check out the links below.