Modern Freezers

So now you know that vapor compression is the principle behind the freezer. But how exactly does it work? At the core is a fast-moving stream of vaporized refrigerant that goes through a cycle inside the freezer.

To get an idea of how it works, picture a river as it winds through the mountains and countryside en route to the ocean. Once it empties out, then it's taken up by clouds, turned into rain, and re-enters that river where it flows to the ocean again. Refrigerant flows and transforms from liquid to gas and back in a similar way.

Advertisement

Today, some of the most commonly used refrigerants are HFCs (hydrofluorocarbons). Other refrigerants, such as CFCs (chlorofluorocarbons) and HCFCs (hydrochlorofluorocarbons) are highly regulated -- and banned from use in many products -- in the United States since they were contribute to depleting the atmospheric ozone layer [source: EPA].

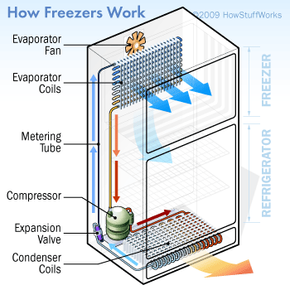

The refrigerant begins the cooling process as a vapor under low pressure. The first freezer component it enters is the compressor (usually found in the lower back of the freezer). The compressor squeezes the vapor's particles, which heats it up and converts it into a high-pressure state.

The hot, pressurized refrigerant is pumped by the compressor through a tube into the next component called a condenser. If you've ever touched the outside of your freezer and felt warmth, that's the heat coming off the condenser coils, which usually sit underneath or at the bottom of the freezer, where they can be exposed to room temperature air and cooled down. As the vapor travels through the condenser coils, it loses the heat but retains its high pressure. It is also converted into a moderately warm temperature.

The now-liquid refrigerant's inherent pressure pushes it through into the next component: the metering tube. This small structure regulates the vapor's pressure so it can head into the next component.

As the liquid refrigerant heads from the small metering tube into the larger evaporator, its pressure drops suddenly, causing it to convert back into a low-pressure vapor. The evaporator also absorbs the heat, which leads to a freezing cold vapor that keeps the unit's temperature cold enough for freezing your food. The vapor then goes back to the compressor to begin the process anew.

Vapor compression isn't the only way to create a super-cold food storage environment. On the next page, we'll talk about other freezing technologies and the different styles of freezers on the market today.