How often do you pay attention to the surfaces you're walking across? I don't think I'd heard the word "terrazzo" to describe a floor until I took a tour of the "Fabulous" Fox Theatre in Atlanta, Ga. The Fox, built in 1929, has a Moorish theme and sports some beautiful terrazzo flooring.

Terrazzo is the Italian word for "terrace," but it also describes a material and technique used for flooring, walls, countertops, benches and more. Terrazzo can be relatively plain or intricately detailed. At first glance, it's easy to confuse terrazzo and mosaic. The difference is that the pieces of marble and glass used in mosaic are usually cubic (known as tesserae) and cut specifically for use in mosaic work. Terrazzo uses different shapes and sizes of chips, laid into a concrete bed (usually dyed), then polished to a shiny surface. They can be glass, marble, granite, stone or even mirrored. Sometimes terrazzo is more of a uniform color, but it can also include sections of different colors. It can be utilitarian, or just as beautiful and decorative as mosaic.

Advertisement

Similar floors have been found in Western Asia that were laid thousands and thousands of years ago. However, Italian mosaic workers are credited with inventing terrazzo in the 15th century. Supposedly, they took leftover pieces from their work home to tile their own floors. Terrazzo is incredibly durable, low maintenance and doesn't easily absorb bacteria or water. That's why it's often used in high-traffic areas like airports, as well as office buildings and hospitals. Terrazzo is also becoming a popular type of flooring in houses. It can even be "green" because depending on the type, it can be made with recycled glass or other materials, and it doesn't emit toxic compounds.

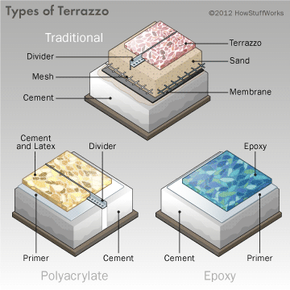

Personally, I'd love terrazzo flooring in my house. But which one would I choose? There are three basic types of terrazzo flooring. We'll start with the traditional, old-world type, also called cementitious terrazzo.

Advertisement