How to Fix and Replace Window Screens

Pinholes in screening are very simple to fix. But, the type of material used to make the window screen will dictate how you repair the pinholes.

If the screening is metal, use a sharply pointed tool to push the strands of wire back toward the hole; you may be able to close the hole completely. If there's still a hole, apply clear nail polish or household cement over it. Let the sealer dry. Apply additional coats until the opening is filled.

Advertisement

With vinyl or fiberglass screening, move the threads back into place. Otherwise, fill tiny holes with clear nail polish or household cement. Be careful not to let any sealer run down the screen. Nail polish may dissolve some types of screen materials.

To close a large hole, cut a patch from a scrap piece of screening, the same type (vinyl, fiberglass, or metal) as the damaged screening. Don't use metal screening made of a different metal; placing two metals together -- steel to copper, for instance -- can cause corrosion.

A vinyl patch is very easy to install, if you can lay the screen flat. Cut a patch about 1/2 inch bigger all around than the hole, and set it over the hole. Place a sheet of aluminum foil over the patch area, shiny side down, and press the patch firmly with a hot iron, being careful not to touch the screen directly with the iron. The heat will fuse the patch onto the screening. If you can't lay the screen flat, sew the patch into place with a needle and nylon thread using a firm running stitch, but don't pull the thread too tight. Apply clear nail polish over the edges of the patch to keep it from fraying.

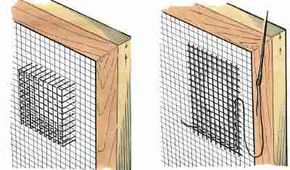

Patch a hole in a metal screen using a larger patch of the same material.

To patch metal screening, cut a square or rectangle about 1 inch bigger all around than hole. Pull out the wires on all four sides to make a wire fringe about 1/2 inch deep around the patch. Bend the fringe wires down sharply at a right angle; use a wood block to make a clean bend on each side of the patch. When the fringe wires are evenly bent, set the patch over the hole in the screen, and press to insert the bent fringe wires through the screening around the hole. The patch should be flat against the screen, covering the hole completely. Fold fringe wires down flat toward the patch's center on the other side of the screen. Then stitch around the entire patch with a needle and nylon thread or with fine wire.

Replacing Window Screens

When a screen has many holes or when metal screening becomes bulged and rusted, consider replacing the screening entirely.

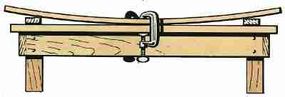

Step 3: Bow or arch the frame for easier installation by weighting or clamping the frame. To use the weight method, set frame the long way across two sawhorses, and hang 10-pound weight from rope around center of frame. To clamp frame into bow, set it on workbench or wide board across two sawhorses. Place C-clamp at center of each long side, holding frame to work surface, and set long piece of scrap wood, such as a 2x4, between frame and work surface at eachend. As you tighten C-clamps, the frame will bow.

Step 4: Set screening across frame, aligned along one unclamped end. Use staple gun loaded with heavy-duty staples to attach screening to wooden frame, placing staples at right angles to frame, about 2 to 3 inches apart. If you're using fiberglass screening, turn cut edge under about 1 inch before stapling it down. When first end is securely stapled, pull loose screening over clamped frame, and stretch it firmly and evenly across to the opposite end. Holding it firmly as you work, staple second end into place, setting staples 2 to 3 inches apart at right angles to frame. Then unclamp or unweight frame; screening should be pulled very tight as it straightens out. Staple two sides into place; trim off any excess screening.

Step 5: Replace molding to cover stapled edges of the screening.