How to Lacquer Furniture

Lacquer is the fastest-drying of the finishes for wooden furniture. It is more durable than shellac -- although it is very thin -- and must be applied in many thin coats. It is available in high-gloss, satin, and matte finishes, in clear form and in several clear stain colors.

Dust-free drying is not a problem, but because lacquer dries so fast -- sometimes almost instantly -- it is very difficult to work with. Brushing lacquers are not recommended for amateur use; spraying lacquers must be applied with a motorized spray gun. Lacquer fumes can be both toxic and explosive. For these reasons, lacquer is not usually used in amateur refinishing. For small jobs, lacquer can be applied with aerosol spray cans. This is expensive, but it works well. It's important to know what type of lacquer to use for the job.

Advertisement

Special Requirements

Lacquer can be used on most woods, but it cannot be used on mahogany and rosewood; the oils in these woods will bleed through the finish. Lacquer can be used over lacquer-base, non-grain-raising (NGR) and water-base stains and over lacquer-base fillers. It cannot be used over other finishes or over oil-base stains or many fillers; the solvents in lacquer will dissolve other finishes and incompatible stains and fillers. Thinned lacquer or shellac or a compatible lacquer-base sanding sealer should be used as a sealer under a lacquer finish.

Lacquer Application Techniques

Wood to be finished with lacquer must be properly prepared, sanded, and sealed. Immediately before applying lacquer, clean the piece of furniture thoroughly with a tack cloth. Use only aerosol spray lacquer, and protect your working area with dropcloths or newspaper. Make sure ventilation is adequate.

Before applying lacquer, test the spray can on a piece of newspaper or cardboard. Spray cans have different patterns of spray; practicing and watching the test spray pattern will give you enough control to properly cover the surface you're finishing.

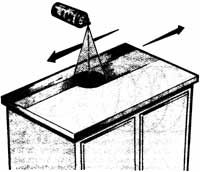

Apply lacquer slowly and evenly, holding the spray can upright about 18 inches away from the surface of the wood.

If you work farther away than this, the lacquer will tend to "orange peel," dimpling like the skin on an orange. If you work closer than 18 inches, too much lacquer may be applied to the surface, causing runs and sags in the finish.

First spray the top edge of the surface; then cover the entire surface in horizontal strips, from side to side, top to bottom. As you work, overlap the lacquer spray patterns slightly.

The edges of each sprayed area are thin; the centers are thick. Overlapping equalizes the thickness of the lacquer film, keeping the surface even. Never try to equalize the film by brushing the lacquer.

Apply only a thin coat of lacquer; this finish must be applied in many thin layers.

Drying and Recoating

Lacquer dries in no more than half an hour, but it must cure completely between coats. Let the newly sprayed wood dry for about 48 hours, or as directed by the manufacturer. Then lightly smooth the surface with No. 000 steel wool, and clean it thoroughly with a tack cloth. Apply a second coat of lacquer as above. For a smoother finish, let the second coat dry for 48 hours, smooth the surface with No. 000 steel wool, and apply a third coat of lacquer as above.

Runs and sags are usually caused by too much lacquer, but they don't always appear on the first couple of coats. The solvent in each coat of lacquer softens the dried lacquer under it to meld the coats together. As you apply more coats of lacquer, the bottom coats soften, and the lacquer film gets thicker; any unevenness can cause sags. For a very rich, deep finish, use many very thin coats of lacquer. Let the lacquer dry completely between coats, and rub the surface between coats with grade FFF powdered pumice and boiled linseed oil on a cheesecloth or felt pad.

After applying the final coat of lacquer, let the piece of furniture dry for 48 hours; then lightly buff the lacquered surface with No. 0000 steel wool. Clean the surface thoroughly with a tack cloth and apply a good-quality paste wax. Buff the waxed surface to a fine gloss.

If you want a finish that is not really permanent, check the next section for information on a paste wax finish, which is easy to apply and maintain.